AT Precision Sales Director Michael Hewitt shares how his company has been transforming waste into high-quality roofing solutions through innovative recycling practices…

The construction industry, by its very nature, is a big user of natural resources. But with growing concerns over climate change and the finite nature of these resources, there is increasing pressure on construction firms to reduce their environmental impact.

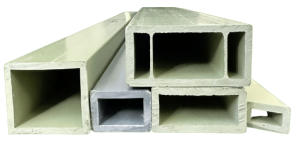

In a groundbreaking move towards sustainable construction, AT Precision took a big step last year in unveiling EcoLath, our cutting-edge range of uPVC roof laths and joists, and an innovative product line that’s testament to our commitment to both environmental responsibility and technological advancement.

EcoLath stands out as a unique offering in the roofing industry, crafted entirely from 100% recycled uPVC. The backbone of this eco-friendly initiative lies in our in-house recycling scheme, a forward-thinking approach that involves the collection of unused and unwanted uPVC offcuts from customers nationwide. These offcuts undergo a transformation through our state-of-the-art extrusion machine, creating robust and sustainable roof laths and joists.

Our successful recycling scheme has allowed us to repurpose well over 50 tonnes of unused uPVC – this not only aligns with our commitment to environmental sustainability, but has also opened doors for us to enter the roofing market with high-quality products.

EcoLath’s advantages over traditional alternatives

The EcoLath range offers a plethora of advantages over traditional timber options. Affordability, knot-free composition, and resistance to rotting, warping, and bending make EcoLath uPVC roof laths and joists the ideal choice for roofing projects.

The innovative use of recycled materials not only promotes sustainability, but also ensures a superior level of durability, contributing to the longevity of any construction project.

Our dedication to sustainable innovation doesn’t stop with roofing – we have also extended our recycling scheme to manufacture 100% recycled thermal reinforcement bars for windows. These bars not only enhance thermal efficiency, but also boast quick installation and an impressive lifespan of 35 years.

A comprehensive offering

In addition to the EcoLath range, we continue to serve both the construction industry and fenestration industry with our Everglide range of bi-fold components, including rollers, guides, and hinges.

Our expertise also extends to security hardware, PVC infill extrusions, and aluminium profile for bi-folds, offering a comprehensive suite of solutions for diverse construction needs.

Looking ahead: A thrilling expansion into roofing

We are thrilled to introduce our EcoLath roof laths and joists to the market. Our commitment to recycling has empowered us to create products that are not only more cost-effective than traditional alternatives, but also deliver unparalleled durability and resistance. We are eager to meet the demands of roofers across the country with our innovative, sustainable solutions.

EcoLath is not just a product – it’s a testament to AT Precision’s vision for a more sustainable and environmentally conscious future in the construction industry. As we continue to pioneer in recycling and innovation, we stand at the forefront of shaping a greener tomorrow for construction professionals and the planet alike.

Get In Touch

Give us a call to discuss your product needs, or to get hardware recommendations and advice

Or contact us online: